Reference for Triumph Laser Welding Process Parameter Settings

Adhere to the following principles during welding:

- The thicker the plate, the larger the welding wire diameter, the higher the power, and the slower the wire feed speed.

- Lower power results in a whiter weld surface, while higher power causes the weld seam to transition from iridescent to black (indicating single-sided formation).

- The welding wire diameter should be selected close to (but not exceeding) the plate thickness, as wire size affects the fullness of the weld.

- Thinner welding wires require narrower scan widths.

Note: The above parameters are for reference only and may require appropriate fine-tuning during application.

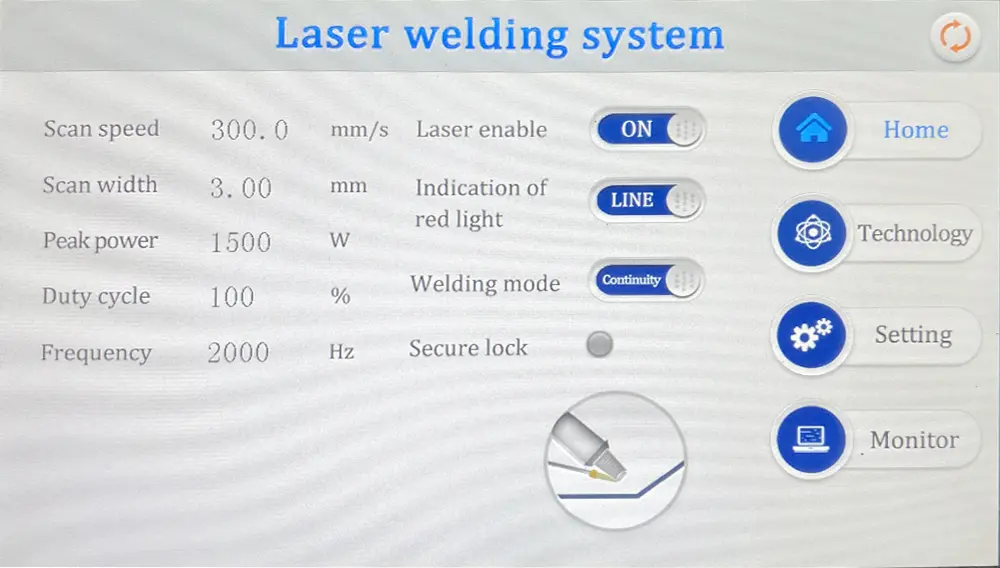

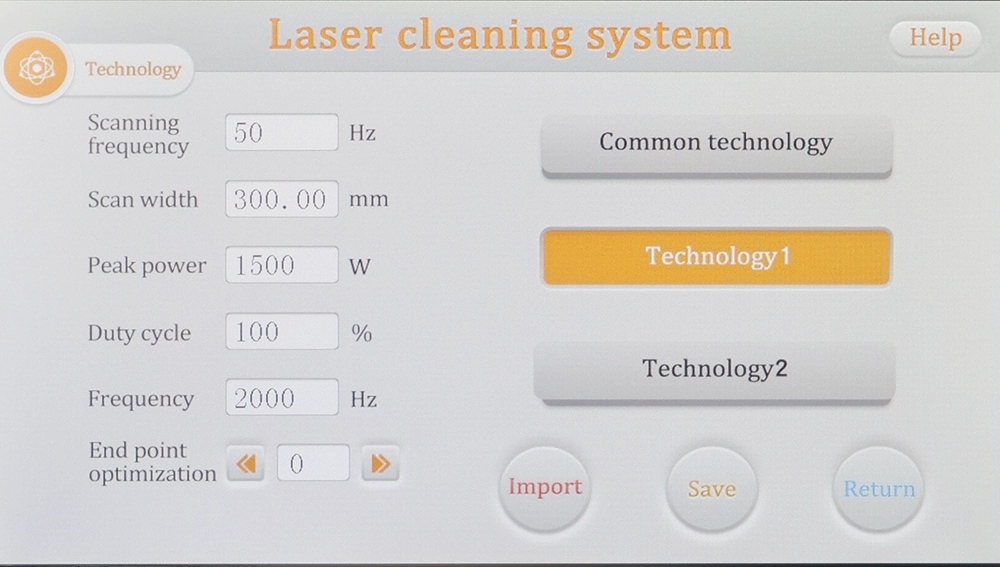

| Material | Thickness/mm | Scan Speed/mm/s | Scan Width/mm | Peak Power/W | Duty Cycle/% | Frequency/Hz | Wire Feeding/cm/m | Welding Wire/mm |

| Carbon Steel | 1 | 300 | 3 | 350 | 100 | 2000 | 60 | 1 |

| Carbon Steel | 2 | 300 | 3 | 700 | 100 | 2000 | 60 | 1.2 |

| Carbon Steel | 3 | 300 | 3 | 1100 | 100 | 2000 | 60 | 1.2 |

| Carbon Steel | 4 | 300 | 3 | 1500 | 100 | 2000 | 60 | 1.6 |

| Carbon Steel | 5 | 220 | 3 | 1800 | 100 | 2000 | 50 | 1.6 |

| Carbon Steel | 6 | 220 | 3 | 2200 | 100 | 2000 | 50 | 1.6 |

| Carbon Steel | 8 | 220 | 3 | 3000 | 100 | 2000 | 40 | 2 |

| Stainless Steel | 0.5 | 300 | 2 | 260 | 100 | 2000 | 80 | ER304 0.8 |

| Stainless Steel | 0.8 | 300 | 2 | 300 | 100 | 2000 | 80 | ER304 0.8 |

| Stainless Steel | 1 | 300 | 2 | 350 | 100 | 2000 | 60 | ER304 1.0 |

| Stainless Steel | 2 | 300 | 3 | 700 | 100 | 2000 | 60 | ER304 1.0 |

| Stainless Steel | 3 | 300 | 3 | 1100 | 100 | 2000 | 60 | ER304 1.2 |

| Stainless Steel | 4 | 300 | 3 | 1500 | 100 | 2000 | 60 | ER304 1.2 |

| Stainless Steel | 5 | 220 | 3 | 1800 | 100 | 2000 | 50 | ER304 1.6 |

| Stainless Steel | 6 | 220 | 3 | 2200 | 100 | 2000 | 50 | ER304 1.6 |

| Stainless Steel | 8 | 220 | 3 | 3000 | 100 | 2000 | 40 | ER304 2.0 |

| Aluminum | 1 | 300 | 3 | 500 | 100 | 2000 | 60 | ER5356 1.0 |

| Aluminum | 2 | 300 | 3 | 800 | 100 | 2000 | 60 | ER5356 1.2 |

| Aluminum | 3 | 300 | 3 | 1400 | 100 | 2000 | 60 | ER5356 1.2 |

| Aluminum | 4 | 300 | 3 | 1800 | 100 | 2000 | 60 | ER5356 1.6 |

| Aluminum | 5 | 220 | 3 | 2000 | 100 | 2000 | 50 | ER5356 1.6 |

Triumphlaser

Triumphlaser