Pulse Laser Cleaning Machine

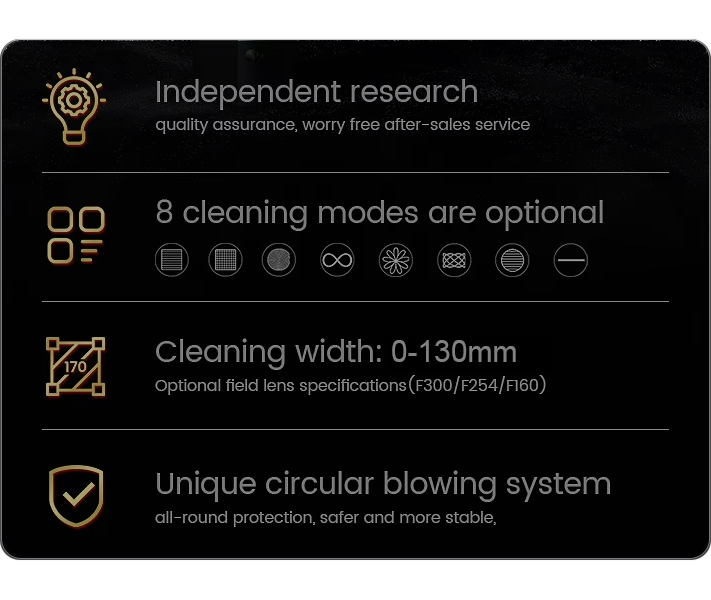

The pulse laser cleaning machine represents a cutting-edge solution designed for efficient and precise surface cleaning. Utilizing high-intensity, ultra-short laser pulses, this advanced technology effectively eliminates contaminants, rust, paint, and other undesired materials from diverse surfaces without causing any damage. Unlike conventional methods that rely on harsh chemicals or abrasive techniques, the pulse laser cleaning machine offers a non-contact, environmentally friendly alternative that preserves the integrity of the underlying material.

This innovative technology marks a new era in surface cleaning and high-tech products. It boasts straightforward installation, operation, and automation capabilities. Once powered on, the machine requires no additional chemicals, water, dust, or media for cleaning. Whether used for handheld applications or automated systems, this laser rust remover effortlessly eradicates surface resin, stains, grease, dirt, coatings, and more with exceptional precision and efficiency.