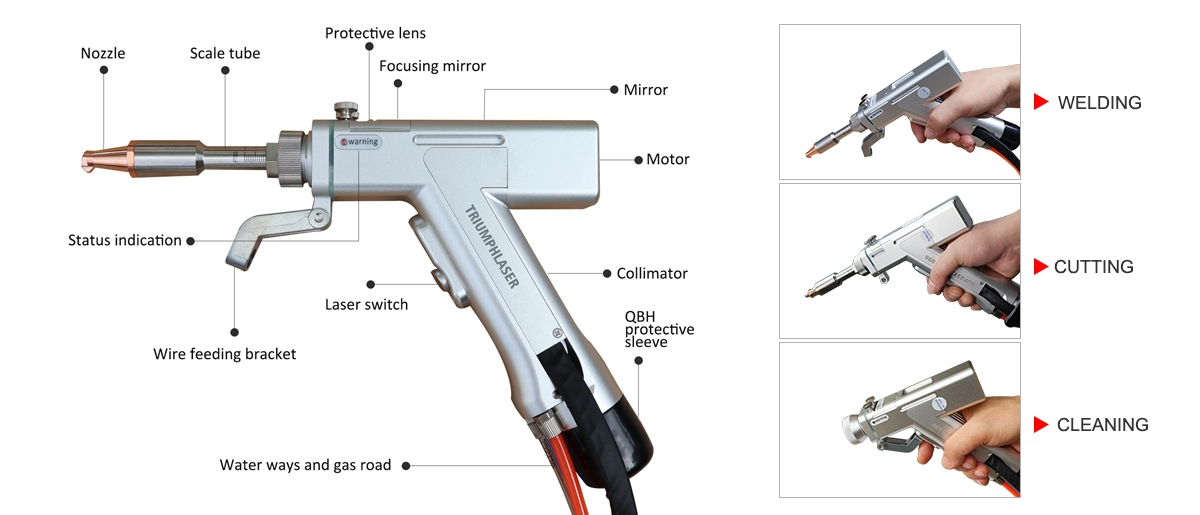

Laser Welding Machine

Laser welding machine is designed to be lightweight and compact, making them easy to carry to different job sites or within a workshop.These machines are user-friendly and require minimal setup compared to traditional welding equipment. This makes them suitable for both professionals and beginners.

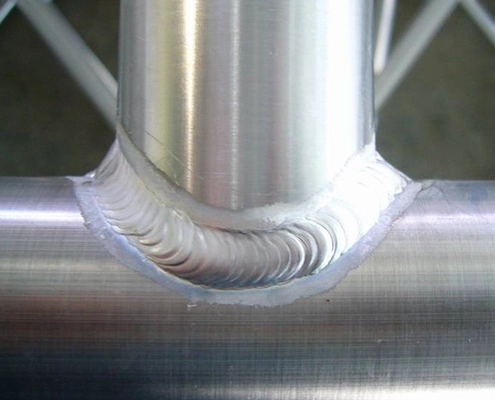

Handheld laser welding provides precise control over the welding process, allowing for fine and intricate welds in various materials. Handheld laser welding machines can often perform welding tasks faster than traditional methods, which can lead to increased productivity. Laser welding is generally safer for operators, as it reduces exposure to harmful fumes and radiation.