The blowing system is a core component that determines the cleaning efficiency and equipment lifespan in laser cleaning processes. Proper configuration of blowing parameters can improve overall performance by over 30%. This article explains the key functions, technical specifications, and operational guidelines for the blowing system.

Core Functions of the Blowing System

- Efficient Contaminant Removal

Removes smoke and debris generated during laser cleaning in real time, preventing recontamination of the workpiece surface or obstruction of the laser beam. - Optical Component Protection

Creates a protective “air curtain” via directed airflow to block splatters from reaching lenses, extending their lifespan. - Process Enhancement

Enhances laser energy concentration on target areas (e.g., oxide layers, grease), improving stripping uniformity.

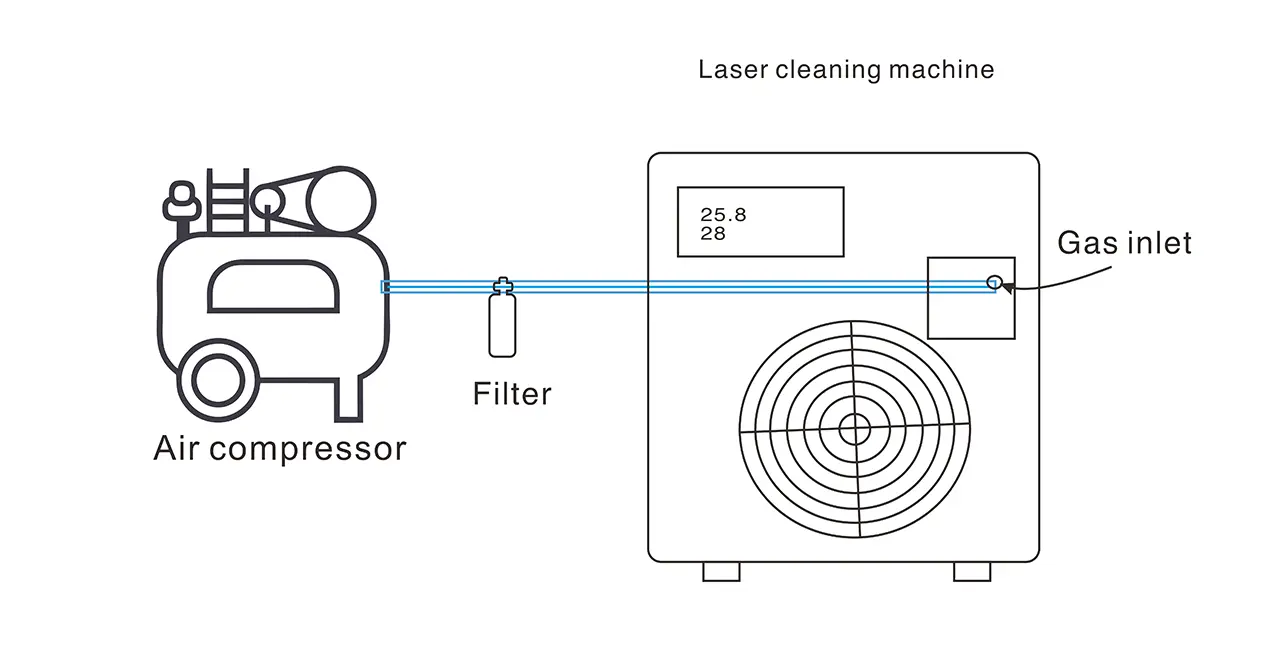

Technical Requirements

- Gas Type Selection

Scenario Recommended Gas General Use Dry, oil-free compressed air Flammable Materials Nitrogen - Pressure & Flow Control

- Pressure Range: 0.2–0.8 MPa

- Low pressure: Ideal for precision cleaning or thin contaminants.

- High pressure: Suitable for stubborn stains or large particles.

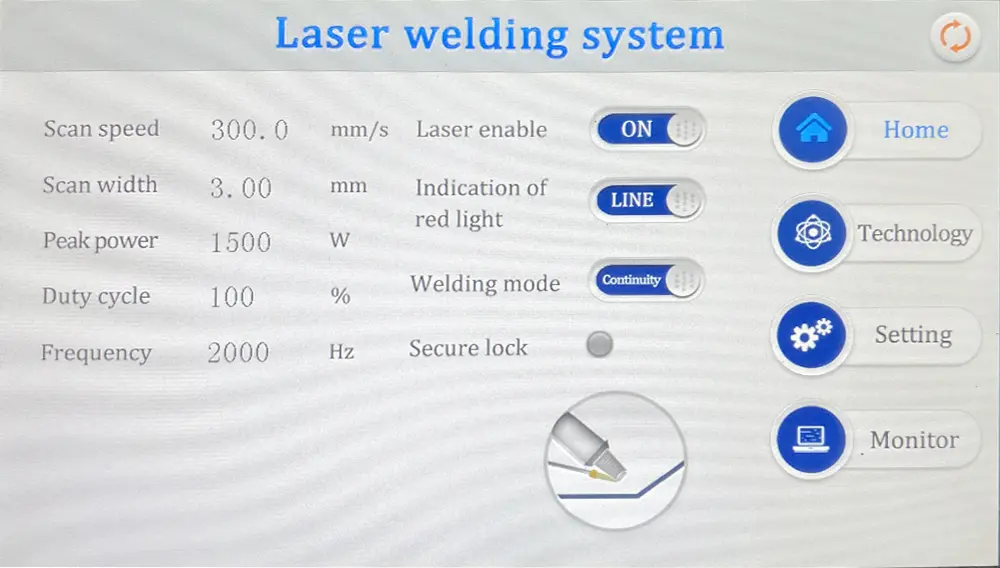

- Flow Matching: Must be synchronized with laser power and scanning speed.

- Pressure Range: 0.2–0.8 MPa

- Nozzle Angle & Position

- Angle: 30°–60°(Relative laser beam)

- Positioning: Cover the cleaning area while avoiding direct airflow toward lenses.

Operation & Maintenance Tips

✅ Daily Checks

- Ensure no nozzle blockage or air leakage.

- Monitor pressure stability (fluctuation <±5%).

✅ Regular Maintenance

- Clean filters weekly; replace high-precision filter cartridges (0.01 μm) quarterly.

- Record lens contamination frequency to optimize blowing parameters.

⚠️Common Issues & Solutions

| Issue | Solution |

| Uneven residue | Adjust nozzle angle or increase pressure |

| Rapid lens contamination | Check gas purity or upgrade filtration |

Proper configuration of the blowing system is crucial for maximizing laser cleaning efficiency. Choosing a professional solution significantly reduces operating costs and extends equipment lifespan.

Triumphlaser

Triumphlaser