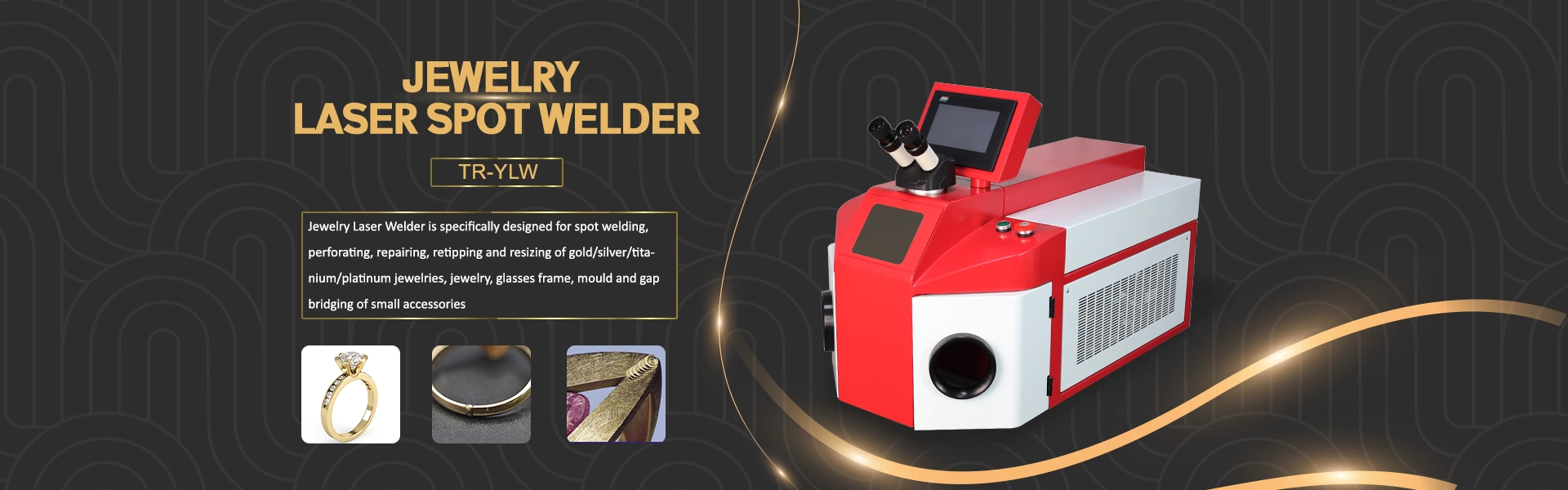

Jewelry Laser Welding Machine

This model jewelry laser welding machine is perfectly suited for Jewelers . The Triumphlaser was not only developed for laser experts but also for technicians intending to simply bond metal to metal. The use of this laser system is quick and easy to learn and you will have the support of our Triumph Laser Team.

The jewelry laser welding machine is specifically for jewelry laser welding of a product, mainly used in gold and silver ornaments of the hole and spot welding blisters. Laser spot welding machine is one of the important aspects of the application of laser material processing technology. The jewelry laser welding machine’s process is heat conduction. That is, laser radiation heats the surface of the work piece. The heat of the surface spreads through the heat conduction to the interior. By controlling the width, energy, peak power and repetition of laser pulse Frequency and other parameters, the workpiece melting, forming a specific pool. Because of jewelry laser welding machine’s unique advantages, has been successfully applied to gold and silver jewelry processing and micro, small parts welding.