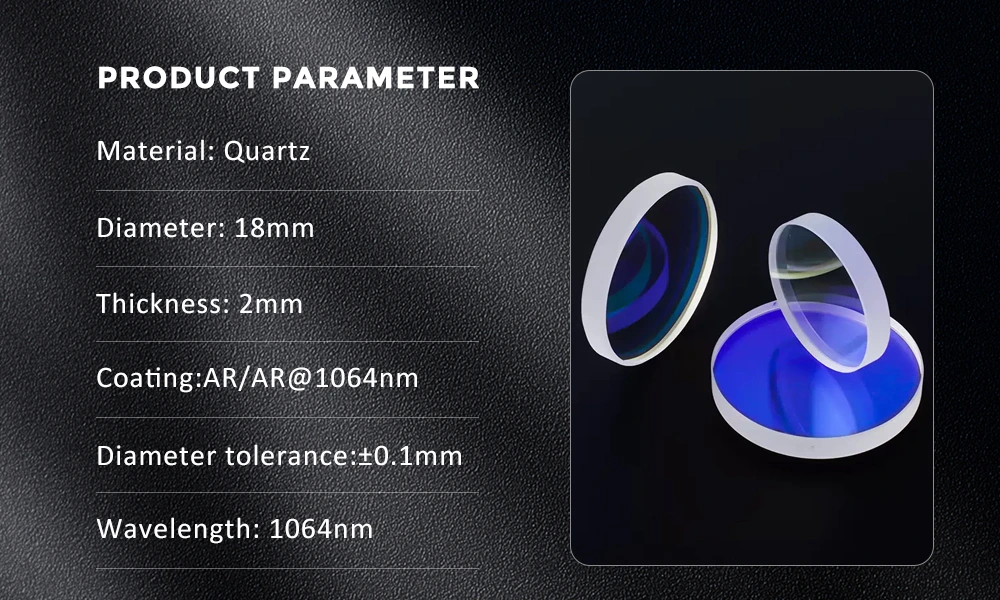

Laser Welding Protective Lens

lmported quartz crystal material laser protective window lens for laser welding gun, double-sided coating transmittance up to 99.9%, not easy to crack, 45 protective all-around angle of 0.5mm,high temperature resistance, strong resistance to laser damage.

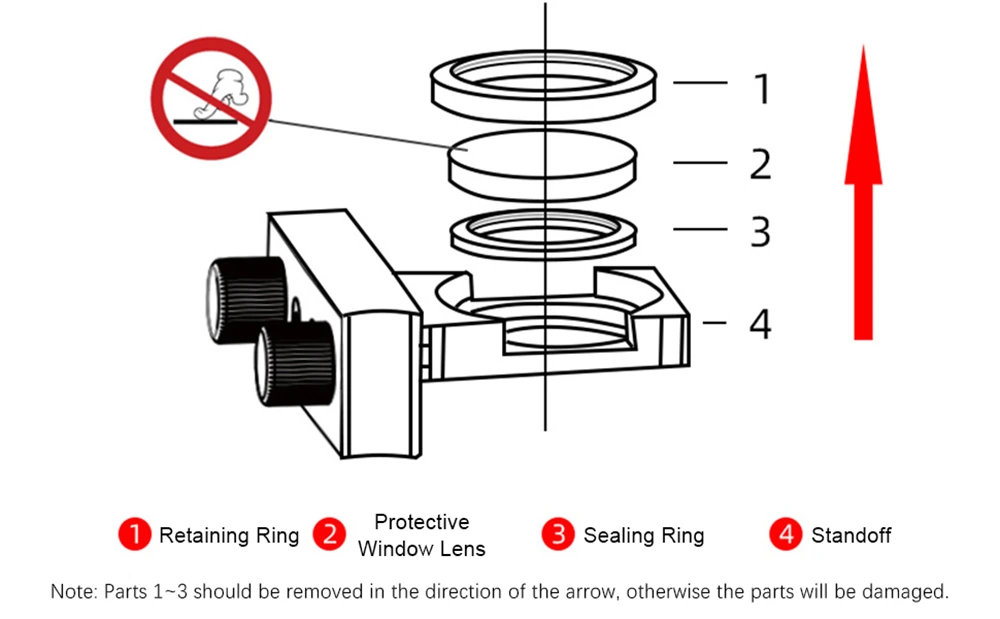

1. Removing the protective lens

(1) After slightly removing the 1 retaining ring, remove the 2 protective lenses.

(2) Place the 2-protective lens cover into a clean container, so that the surface of the lens does not come into contact with non-gaseous substances.

2. Cleaning the protective lenses

(1) Clean the protective lenses with a dust-free cleaning rod dipped in isopropyl alcohol solvent, and then blow off the adhering particles and other foreign matter by using the PiTiger air blower to draw clean air; repeat several times until the lenses are clean.

(2) Repeat until the lens is clean.

(3) If the protective lens is impossible to clean or damaged, it must be replaced with a new one.

3. Check the seal

(1) Check the sealing ring for deformation or gaps that may cause air leakage.

(2) The seal must not fall onto the ground or other dirty, dusty, or rough environments.

4. Installation of protective lenses

(1) Carefully place the cleaned 2 protective lens into the 4 support.

(2) Put in the 1 fixing ring, and be careful to check that the 3 seal is under the protective lens.