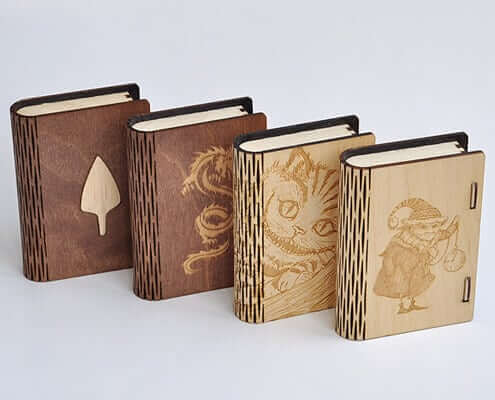

Wood laser cutting engraving

Triumphlaser woodworking lasers are optimally suited for laser engraving and laser cutting wood and timber, such as for example toys, decorative items, artistic craftwork, souvenirs, Christmas decorations, gifts, architectural models, and for wood inlays.

Project description

Since wood is a natural material, the laser user must consider various characteristics, such as e. g. the density and the resin content, when working with wood. Soft wood types, such Balsa wood, require a lower laser power and can be cut at a higher speed. Hard wood, as an example of dense wood types, on the other hand, requires a higher laser power. When working with MDF, which consists of glued wood fibers, Triumphlaser recommends the use of compressed air.